I recently started making my own craft beef jerky. I have ten batches under my belt at this point. I started with a pellet-smoker at 160 degrees F which gave me incredible flavor, but the appearance of the jerk was always burnt looking and the batches were VERY uneven in their drying times. I had to babysit the batches to pull pieces off anywhere from 3-5 hours. So, I added a dehydrator to my arsenal about six batches ago.

The GOAL was consistency. The result was consistently inconsistent.

It only took two batches in my new Cabela's 80-liter Commercial Grade dehydrator for me to realize I was playing the same game. I started at the top-end of the temperature range for the unit, 165 degrees F. Drying times ranged from 3 1/2 to 5 1/2 hours. This was one eye-of-round, sliced consistently with a slicer to 3/16". This wide range of drying times in a digitally controlled dehydrator was a bit shocking to me. Not only were the drying times just as inconsistent as the pellet-smoker, the appearance of my jerky was also still burnt looking.

My next two batches in the dehydrator were done at 145 degrees F. I was hoping that the decrease in temperature would address the appearance issue. Thankfully, it did. These two batches were visually still dark in color, but a vast improvement for my personal taste. However, pieces were still ready to come off the dehydrator ranging from 4 to 7 hours. Why have the dehydrator gods forsaken me?

“When you're handed lemons, you roll up your sleeves and learn about micro-controllers, temperature/humidity sensors and you trick out your dehydrator to push readings to the cloud for deeper analysis - Nate Jackson”

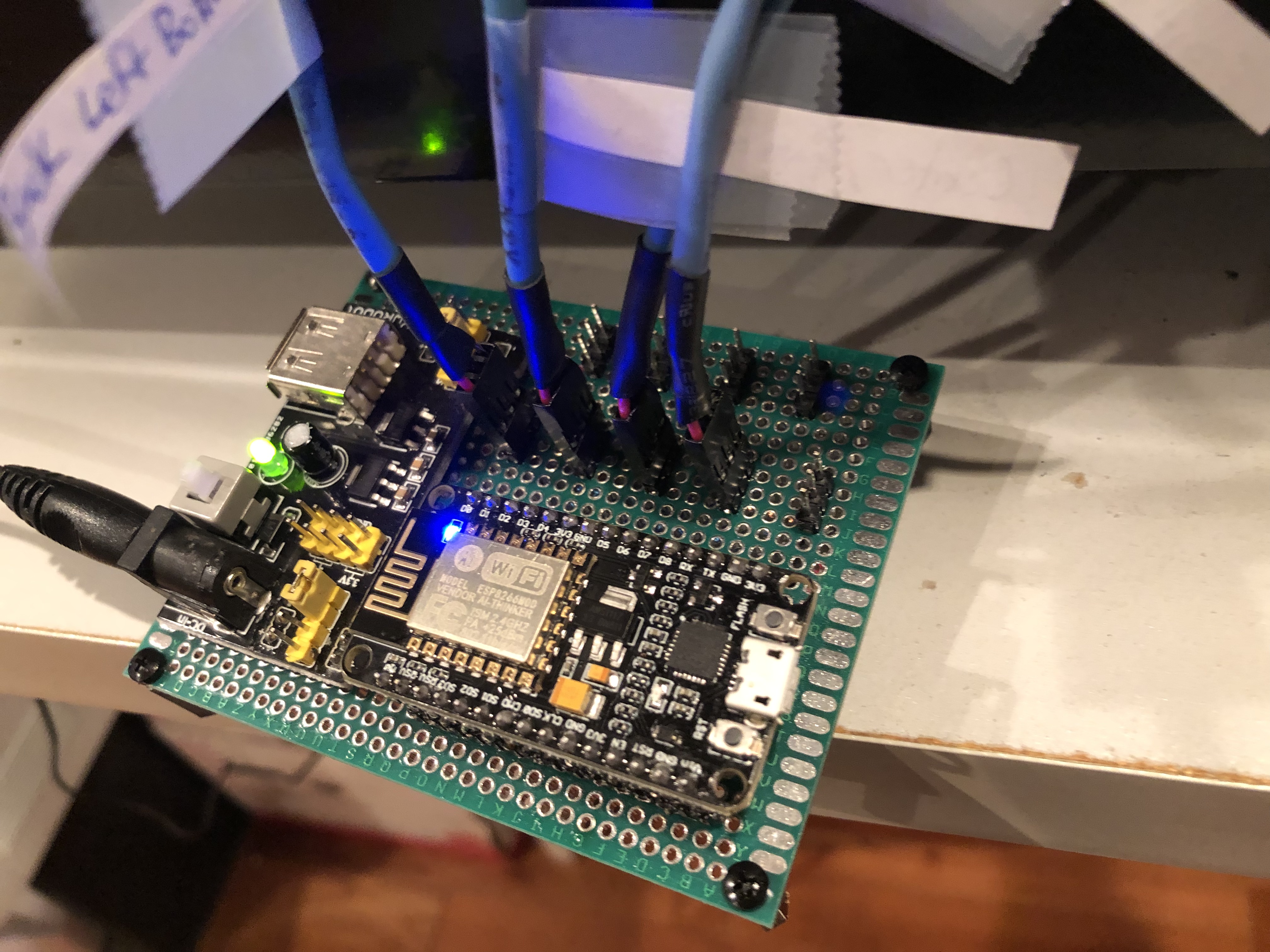

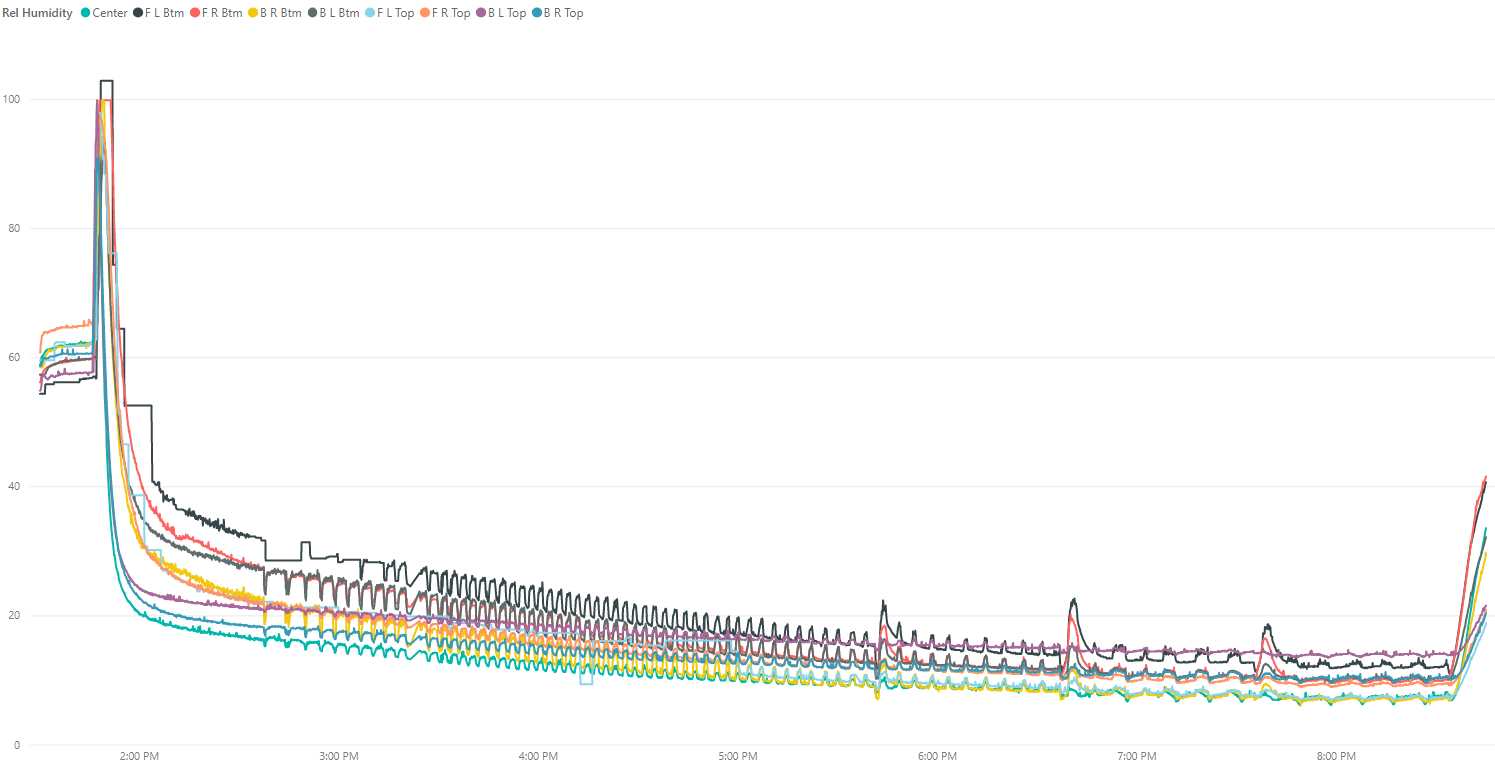

I'm a software developer by day. I did a bit of digital circuit design in the early 90s, but haven't really kept up with things since then. I thought I'd take this opportunity to re-introduce myself to the world of micro-controllers and instrument my dehydrator with sensors in nine zones(yes, 9!) to capture and store data over the entire drying time.

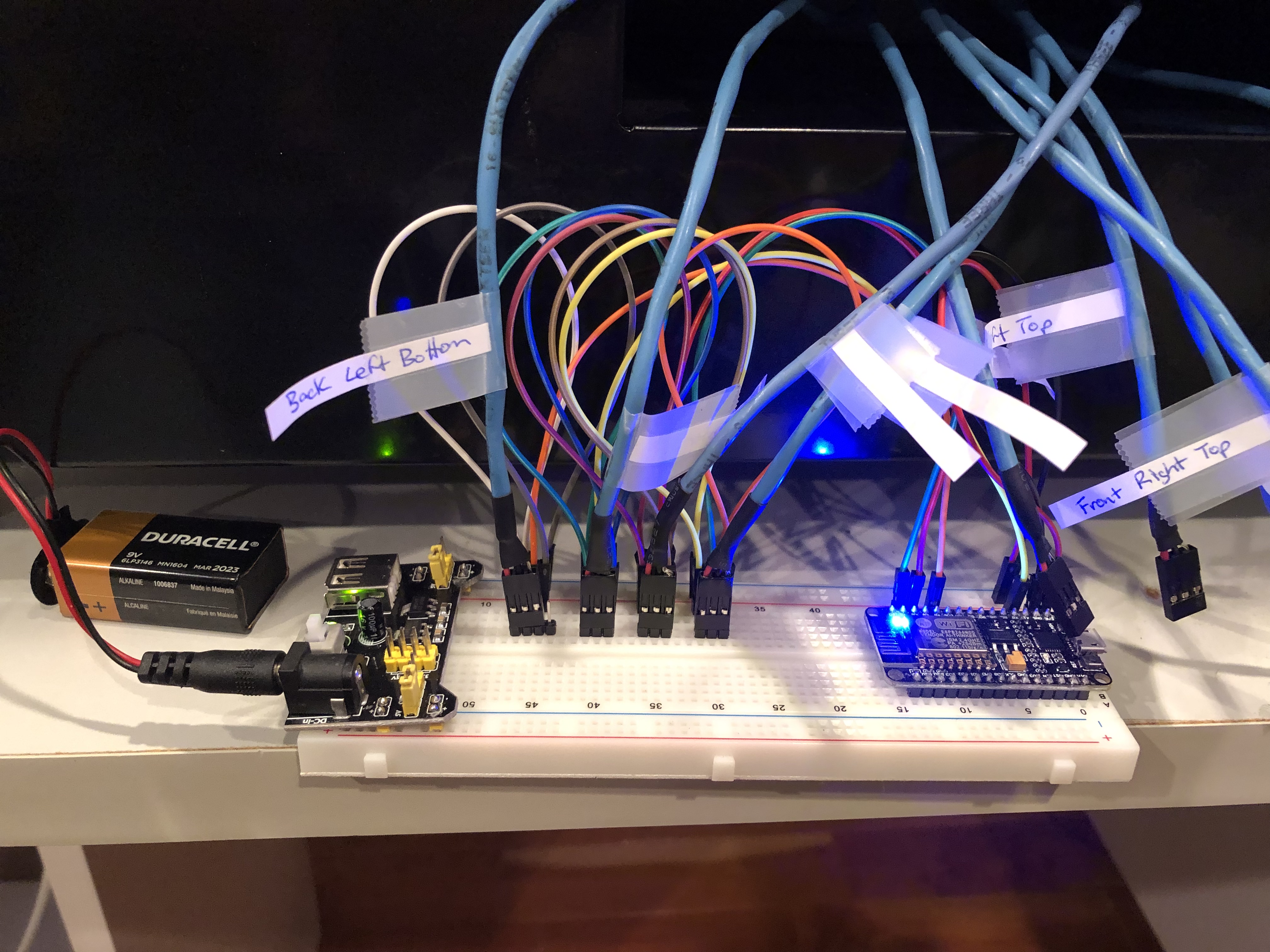

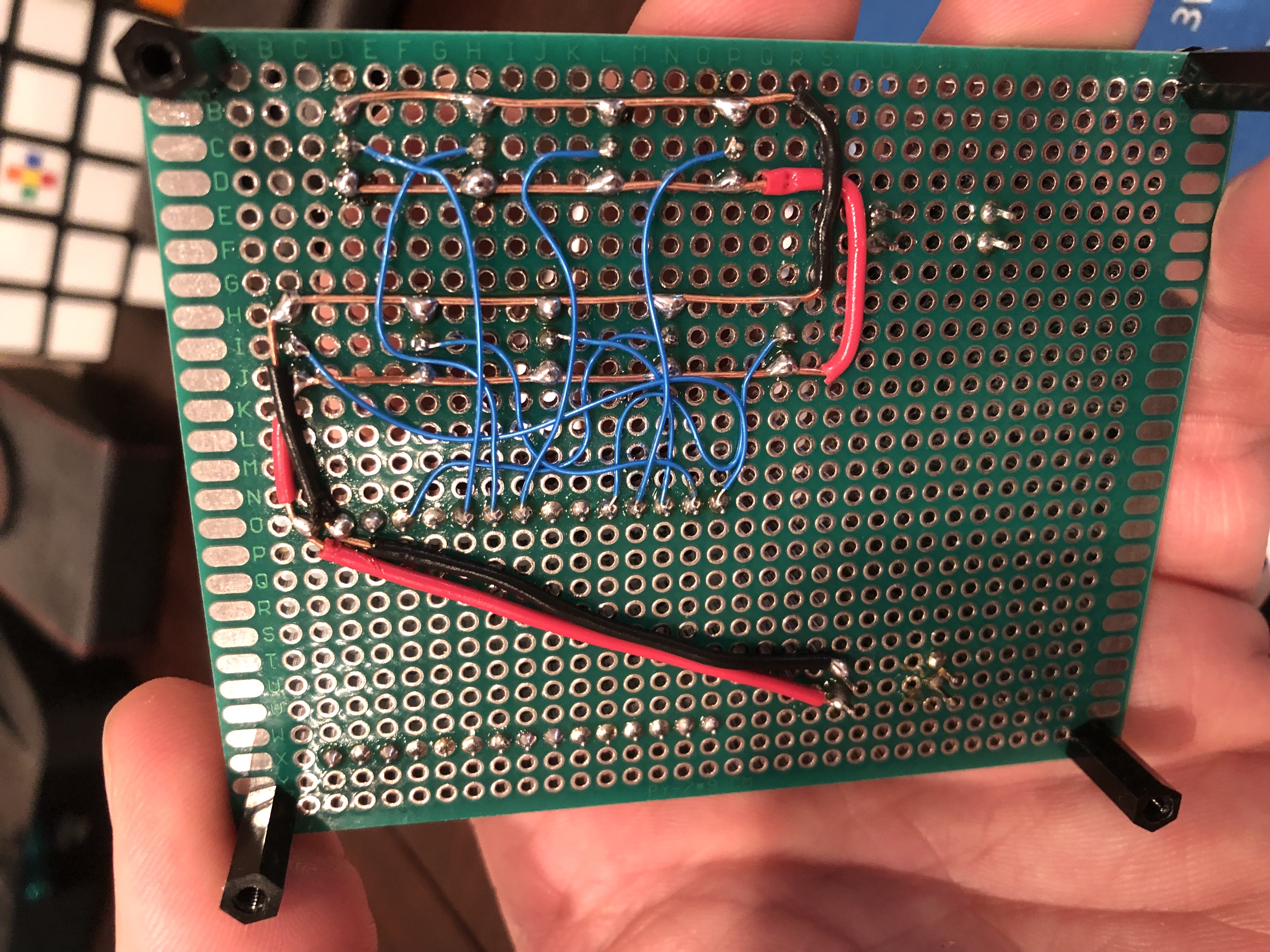

I built a circuit board that allowed me to collect data from nine(9!) temperature/humidity sensors every two seconds during my dehydration time. I store the data in the cloud (you didn't know Jerky making and "the cloud" went together did ya!?) and then I charted the results on some graphs to help understand what the heck is happening inside that 2' x 2' dehydrator!

I embarked upon wiring up a sensor in all eight corners of my dehydrator, plus one smack-dab in the middle of the middle rack. That is admittedly a lot of sensors for what is less that a 2' x 2' cube.

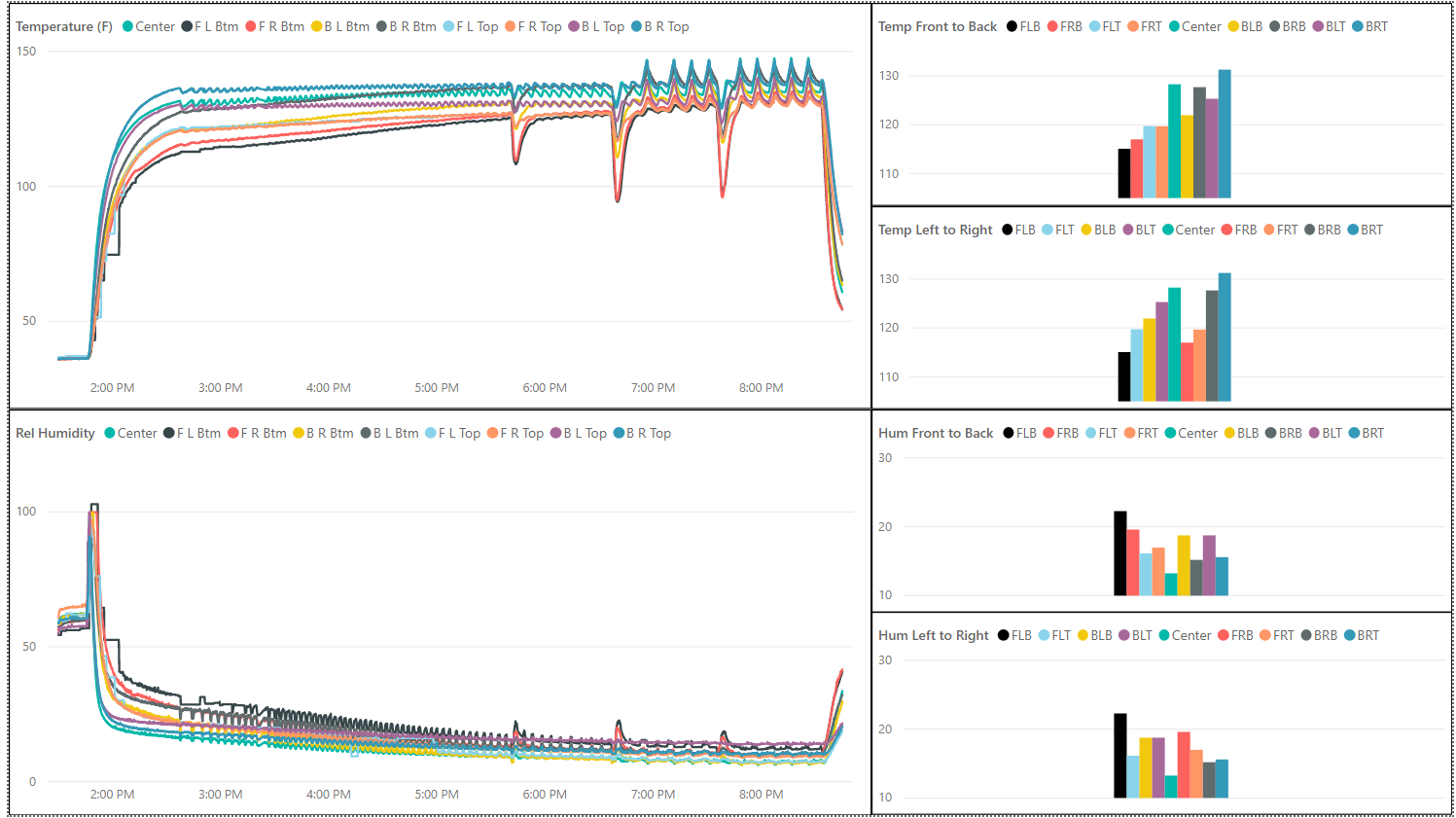

So, what have I learned about my dehydrator?

- There is often a 12-14 degree F difference between hottest and coldest zones

- The back is always 6-12 degrees F warmer that the front

- The right side is always 4-6 degrees F warmer than the left

- The top is always 4-5 degrees F warmer than the bottom

- The center always shows as warmer and dryer, yet the items in this zone are generally near the last to be ready

This all coorelates nicely with my simple observations. I always pull my first pieces from the back-top, then the lower-back. They continue to come off, with pieces in the front being last. Pieces in the lower-front left of my dehydrator are often relocated to "higher" spots.

Note: This is not a knock on the Cabela's 80-liter dehydrator. I'm pretty happy with it. Until today, I thought I couldn't rotate the racks due to that weird notch in the back of the unit. But, I was pleasantly surprised today to learn the racks still fit and the door closes. So, future batches easily swap front to back to address the temp difference.

Tap on the pics below to see a gallery of the images with captions explaining what is in each shot.